The world of print is undergoing an exciting transformation, not a decline. While smartphone screens dominate out attention, print remains a powerful and impactful medium. Forward-thinking commercial printers are embracing innovation to create unique and engaging printed experiences that complement the digital world, not compete with it. By offering creative enhancements that go beyond ‘just ink on paper,’ print can capture consumer attention in ways that a tiny screen simply cannot.

Growth Opportunities

Production print is not dead. Did you know that the production print industry has expanded over the years and includes a wide range of projects? Large format printers have been used to print everything from posters, banners and signs – to wallpaper, vehicle graphics and packaging.

In fact, the U.S. packaging industry has experienced a growth spurt in recent years. This trend is expected to continue through 2029 or longer and is forecasted to see the highest growth in eco-friendly packaging, especially in paper and paperboard packaging products.

RELATED: Guide to Standard Dots Per Inch for Printed Work

In this article we’ll discuss three examples that show how production print is alive and well, especially in the packaging print industry. Let’s dive in and learn about:

Short-Run Packaging Print Jobs

There is a growing need for short-run jobs with quick turnaround times that large packaging printers often are not able to accommodate efficiently. This trend is creating an opportunity for commercial printers with a minimal amount of change to their core business.

Innovative printers will offer the ability to print special editions, re-releases and personalized products. These specialized short-run projects will fit nicely on a digital press.

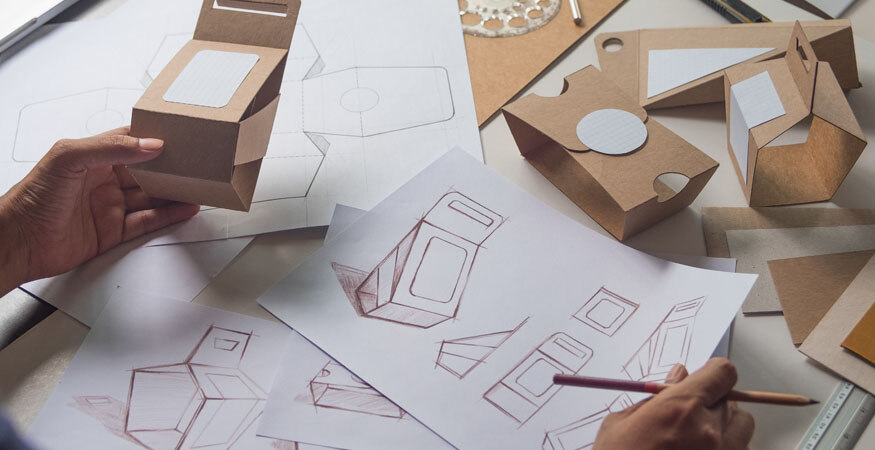

Furthermore, if you specialize in folding carton work, why not test a new packaging design, printed on a digital device and then send it out for approval? Fit, content and color accuracy can all be achieved to match the final production run.

RELATED: Why Color Management Matters

Package Prototyping

Along with this need for short-run packaging will come an opportunity to offer design and prototyping as a new revenue stream. Package prototyping is another area where printers can differentiate themselves and win lucrative new business. Prototyping is typically a one-off or ultra short-run job, which will usually be used for fit and content. A printed package protype provides a visual representation of the finished piece without the substantial investment of a typical press run. It is a great way to win long-term business by proving yourself to new clients.

With finishing technology like the Duplo DPC-400 Digital Die Cutter, printers can create short-run packaging and then cut the printed pieces without the need for a physical die. The DPC-400 can cut, kiss cut, and score a wide range of substrates, including laminates, adhesives, and synthetic stocks up to 14” x 20” in size. The Duplo DPC-400 is the perfect device for environments where a 4’ x 8’ routing table just physically won’t fit.

RELATED: The Benefits of Upgrading Your Large Format Printers

Coating Options to “Wow” Your Customers

As part of the packaging print process, there will be a need for UV or aqueous coating. Although specialized, many manufacturers formulate coatings for digital (toner) printing. Smaller offline coating devices like the Duplo Ultra 300Ai/300A UV Coater, for example, apply a high-quality gloss or satin finish to a wide range of offset and digitally-printed applications at a reasonable price point. Depending on what kind of result you want to achieve, coatings work to enhance the desired outcome. You can flood coat to protect the printed piece or spot coat to extenuate an image or graphic and make it pop off the page. UV coating is exceptionally durable, which makes it useful for mailed pieces to protect against scuffing. Most coatings are free of solvents and do not emit VOCs when cured, meaning they are environmentally friendly.

For printers, printing is not just a job – it is an art! Those that can deliver craftsmanship and innovation will thrive, even in a digital world. This is why printers need to be nimble and flexible. In this manner, small to medium-sized commercial print businesses are expected to see additional opportunities to capture more specialized work.

If you are interested in some of the ways digital print and new finishing technology can help your print business grow, we’re here to help! Contact the production print experts Gordon Flesch Company to learn more.